MANEX provides design and realisation of projects in the field of automation of technological lines. Automated handling systems are designed and produced to the needs of specific customer. Technical solutions and used equipment are always dimensioned to fulfil all given quality and performance parameters of the user. Service and after-sale services are taken for granted.

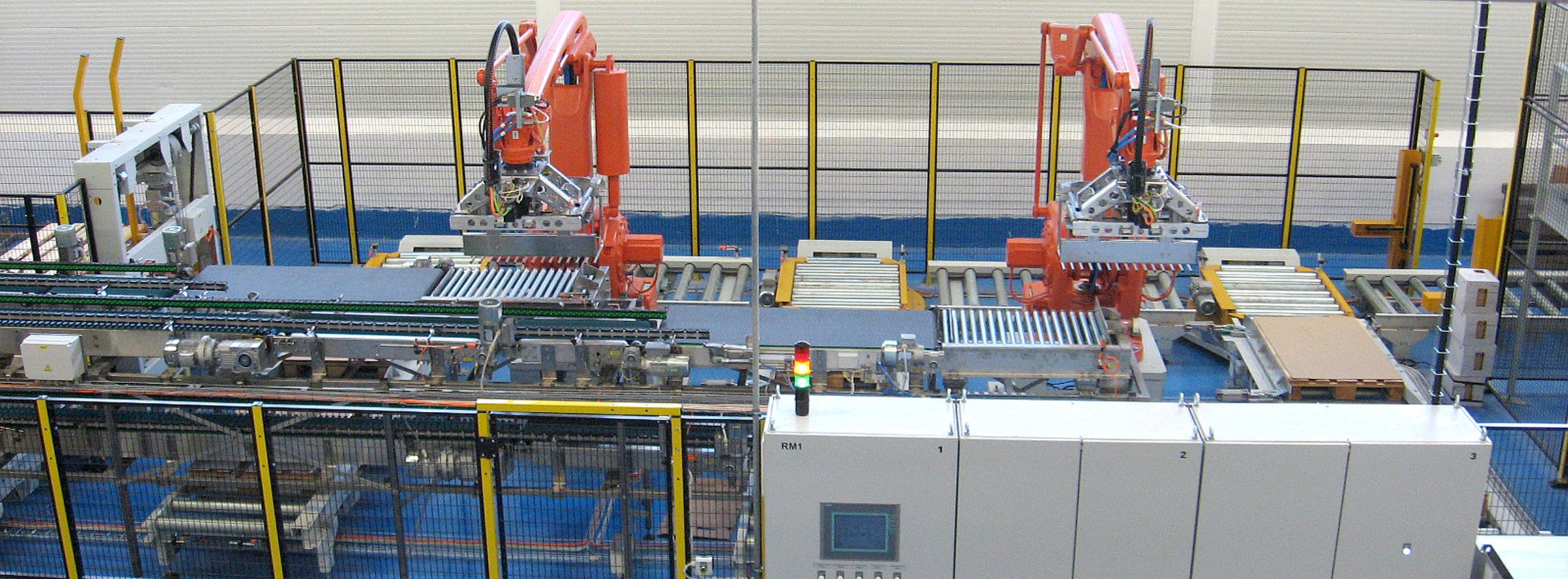

ROBOTIC SYSTEMS

Applications with industrial robots are currently the most used example of automated workplace. Due to high variability and good performance parameters the industrial robots proved useful in various applications such as e.g. robotic manipulation or robotic palletizing. However MANEX, integrator of robots, uses them most frequently in food, beverage, chemical, timber and automotive industry. We successfully integrate also the most modern „pick and place“ robots which are used for fast handling of small and light objects. Within projects MANEX uses and integrates industrial robots of marks ABB, KUKA. MANEX also offers design and production of robot handling heads, manipulation heads, grippers.

Main benefits of use of robotic handling systems:

- high productivity, reliability and high repeated precision

- easy adaptation of robot to new type of product

- low cycle times and high performance

- acceptable acquisition costs

CONVEYING SYSTEMS

MANEX specializes in production of automated conveying systems mainly for the following fields:

TRANSPORT | HANDLING | PACKAGING and FIXATION | FILLING

TRANSPORT - TRANSPORT CONVEYING SYSTEMS

Transport conveying systems delivered by company MANEX are created by conveying tracks which consist of partial conveying modules and conveyors. In term of production type MANEX focuses mainly on food, paper, timber, construction , chemical and automotive industry.

The transport conveying system can be the only automated part within all production however in most cases it forms only subsystem of all automated line or robotic system.

Even if the whole transport system is formed by standard and „special“ conveying modules due to large amount of various types of transported products and specific requirements for performance and disposition requirements, each transport system as a whole is a unique project.

MANIPULATION - AUTOMATED HANDLING SYSTEMS

MANEX realizes automated handling systems for handling of single products, group packs or complete already packed pallets. In term of performed act they are: palletizing/depalletizing systems, stackers and destackers, inserters and unloaders,or workplaces with specific way of handling.

MANEX realizes applications from the simplest handling consisting of simple movement up to complicated multiplied acts and complicated trajectory.

In term of goods type – they are mostly cartons ( glass, solid objects, fluids) bottles and packages of PET bottles, barrels, various formats of boards, pallets, bags, scrolls and windings, etc.

MANIPULATION - MULTI-AXIAL LINEAR MANIPULATORS

These are one axis, two axis and three axis portal modules and linear technologies with useful loading up to several tons. These devices consist of module elements enabling high loading and dynamics at maintaining precision of positioning and silent running. Multi-axial linear manipulators GUDEL are designed within projects.

Basic benefits of use of linear manipulators:

- high productivity, reliability and high repeated precision

- large ranges of performed movements and tracks

- high performance

- handling by single purpose equipment

MANIPULATION - SINGLE-PURPOSE EQUIPMENT

For use of specific types of manipulation activities where in term of technical possibilities or from economic point of view the use of industrial robots or linear manipulators is not suitable, these activities are solved by help of single purpose machines and equipment. These devices are objects of constructional development on the basis of given requirements and sometimes they can be also unique prototype devices. For their repeated use however they are often proven construction solutions or specifically a type line which has to be adjusted to the specific features of the product.

Basic benefits of single purpose machines and equipment:

- construction and performance parameters of equipment dimensioned precisely for specific requirements of the assignment

- more simple handling tailored directly to the specific operation

- acceptable acquisition costs

PACKAGING and FIXATION

Company MANEX realizes within its projects a large part of automated packaging workplaces which are either part of a larger whole such as the complete filling or production line or it is the delivery of autonomous packaging equipment.

FILLING

Company MANEX delivers filling lines and technological equipment of lines for branches of food industry, above all for wine factories, for producers of spirits and liquors, for breweries, producers of mineral and table waters, dairies, etc. Automated lines of MANEX are able to fill : mineral and table waters | still and sparkling non-alcoholic beverages | still and sparkling wines | beer | spirits and liquors